Planning and monitoring preventive and corrective maintenance

MainTrack enables users to record, plan and monitor both preventative and corrective maintenance of the vehicle fleet, and to manage all information in electronic format. In this way it enables the most efficient management of vehicles and maintenance activities.

Minimise the effort required to monitor, plan and undertake all maintenance activities

Minimise locomotive unavailability due to maintenance activities

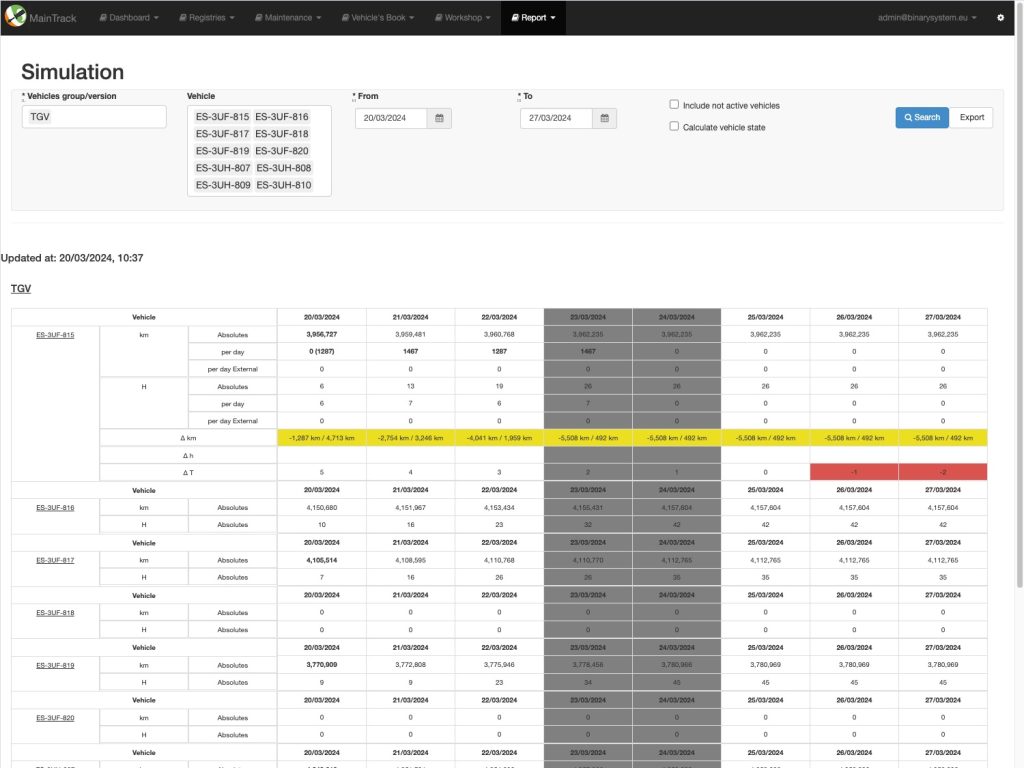

Manage preventative maintenance plans based on actual KMs travelled

Maintenance teams can plan preventative maintenance based on KMs travelled data directly from LogiShift.

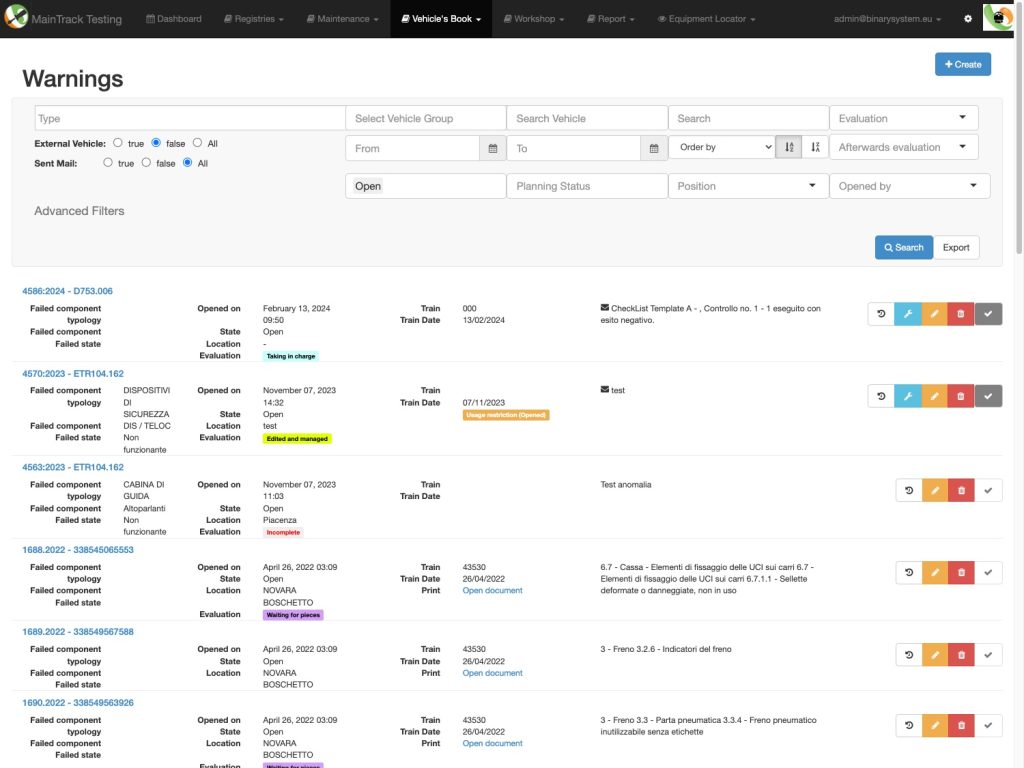

Corrective maintenance is efficiently captured by users, who can record issues in real time via a mobile application.

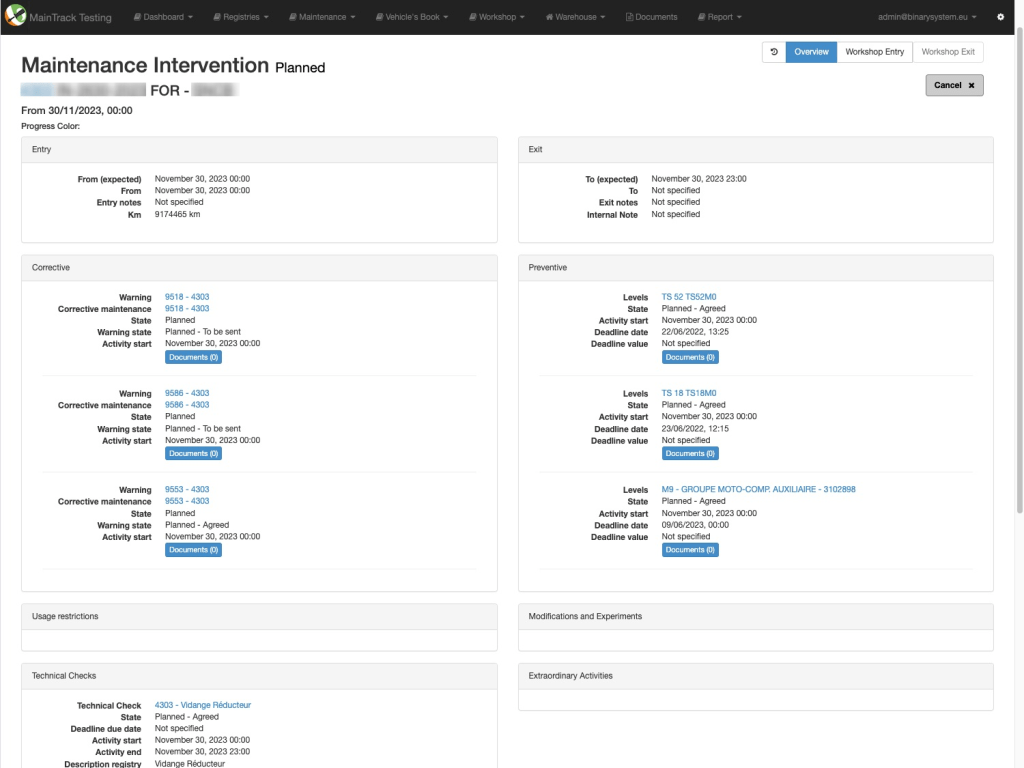

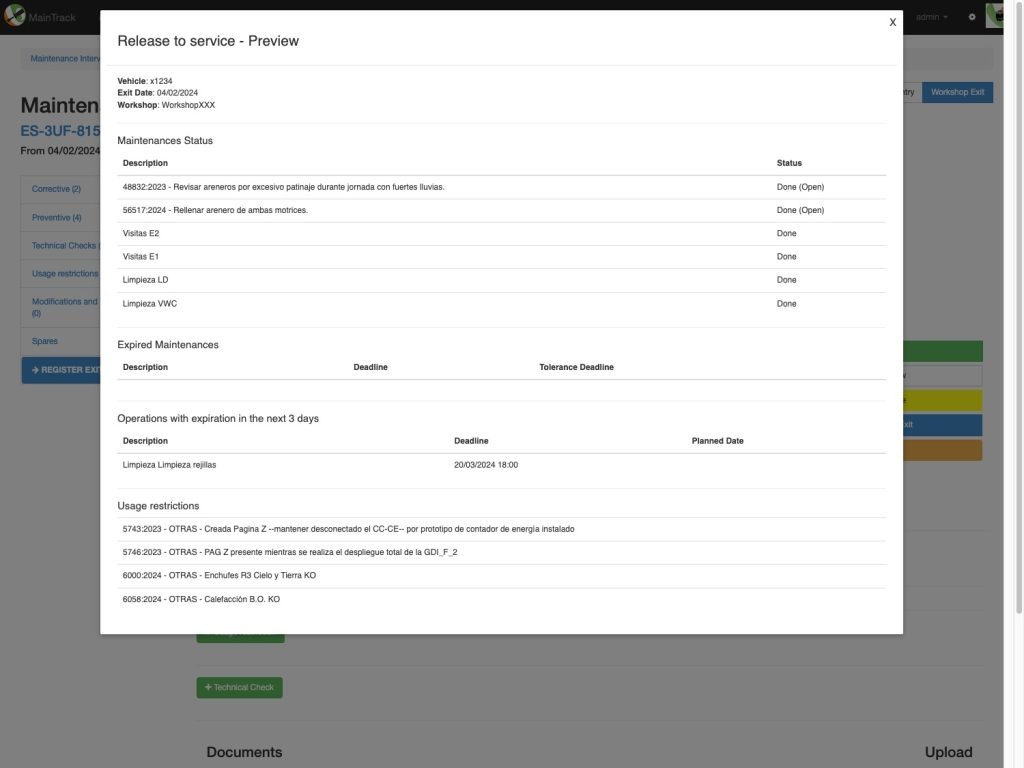

Enables maintenance teams to address multiple requirements in a single intervention, thereby minimising locomotive disruption.

Communicates with other parts of the system – for example, informing planning teams via LogiShift when a locomotive is back in service and can be considered for shifts.

Consult the on-board book digitized by APP, report new anomalies and fill in the checklists of pre-train departure.

Track each technician’s activities and qualifications, ensuring high safety standards.

Configure all costs to be associated with maintenance activities, generating related expense reports.

Monitor and manage the status of your maintenance equipment.

Identifies the location of the equipment, such as brackets and tail lights.

Monitors in real time the stocks of each depot. Track inputs and outputs. Manages replenishment orders, reservations and Bills of Lading. Generate reports for monitoring and alerts for parts below reorder threshold.

Monitor the spare parts installed on the vehicle, keep track of the mileage of each spare and manage the related deadlines.

Through a single platform suite, SoftRail empowers teams to easily manage and organise all operational personnel, rolling stock and safety activities. The SoftRail solution is divided into several modules specifically designed to meet the requirements of each customer and type of user.

Operating individually or as an integrated suite, SoftRail modules ensure fully optimised operations to maximise cost savings, while prioritising and amplifying safety standards.

AI-Driven efficient, reliable and coordinated planning/scheduling of employees and vehicles

Planning and monitoring preventive and corrective maintenance

Real-time digital communications portal for all documentation

Plan, monitor and manage all training, refreshing activities and employee audits.

Management and control over all railway shunting operations

Real-time data covering inspections and verification activities